English

English  Esperanto

Esperanto Afrikaans

Afrikaans Català

Català שפה עברית

שפה עברית Cymraeg

Cymraeg Galego

Galego Latviešu

Latviešu icelandic

icelandic ייִדיש

ייִדיש беларускі

беларускі Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ភាសាខ្មែរ

ភាសាខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Тоҷикӣ

Тоҷикӣ O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra Հայերեն

Հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba অসমীয়া

অসমীয়া ଓଡିଆ

ଓଡିଆ Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

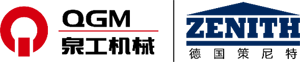

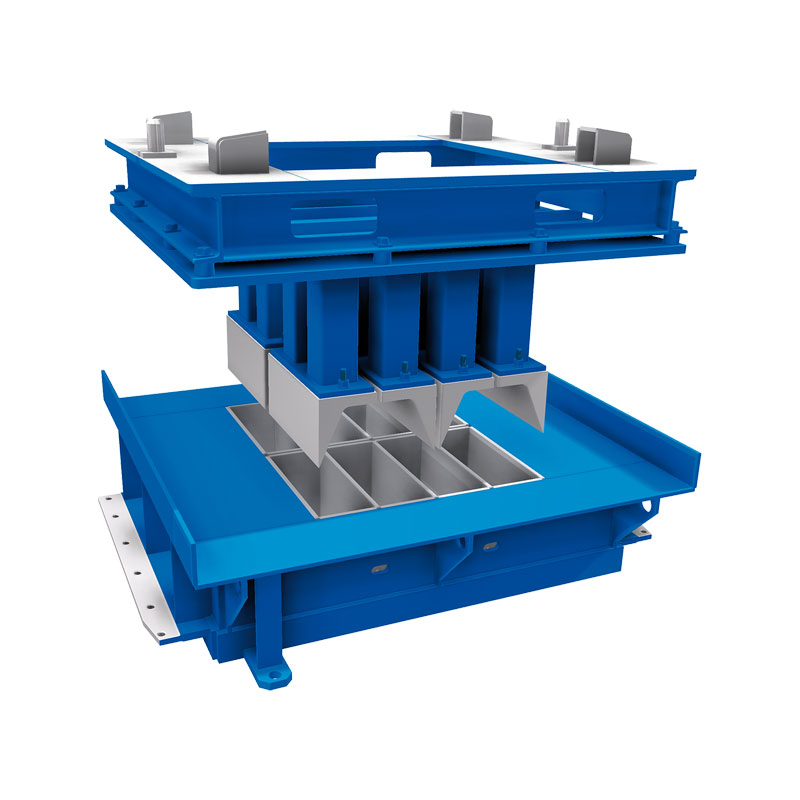

Paver Mold

Romela Lipatlisiso

Joaloka moetsi ea hloahloa, re rata ho u fa Paver Mold. QGM paver hlobo e nka tšepe e tlase ea carbon alloy high-power carburizing tšepe 'me e kopanya theknoloji e nepahetseng ea ho itšeha ka mokhoa o nepahetseng oa CNC processing technolbgy le thekenoloji ea ho hlahloba 3D ho fa bareki mokhoa oa ho iketsetsa hlobo. Theknoloji ena e ka etsa moralo oa lefeela la li-contours le libopeho tsa geometri. Ho hlaka ha eona ke 0.3-0.4mm, ka likhutlo tse nepahetseng tse otlolohileng: mabota a mahlakoreng a monokotšoai. Li-Pavers tse hlahisoang ke QGM li bonolo ho li etsa, li nepahetse haholo, ha ho na li-burrs tse potolohileng. Moulds e ka lemoha moralo oa dijithale oa freesurface le moralo o fapanyetsanoang oa lipoleiti tsa khatello.

E le ho etsa bonnete ba ho tšoarella ha hlobo, QGM paver hlobo e amohela phekolo ea carbunizing., liforeimi tsa hlobo le lipoleiti tsa khatello li thatafalitsoe 60-63HRC, 'me botebo bo thata ba mirnimuim ke 1.2m. Ho ea ka likopo tsa bareki, hlobo e ka etsoa le e entsoeng ka ho tjheseletsa kapa ho notlela modular khoele.

Re fana ka Paver Molds ea boleng bo holimo bakeng sa mefuta eohle ea mechini le lisebelisoa tsa lisebelisoa ka moralo o latelang:

A) MOULD DIRA LELABAKA LEKHALA

Botenya ba marang-rang bo ka khoneha

Tšebeliso e nepahetseng ea hlobo

Tlhaloso ea lieta tse itšetlehileng ka mochine ea 0,2-0,5 mm

Mabota a mahlakoreng a li-counter-conical a khoneha

Ha ho na li-grooves tse hlokahalang

Moqapi o tloaelehileng oa mechine ea tlhahiso ea multilayer

Moqapi oa lakane oa boikhethelo

Ka digitalization mahala holim'a moralo oa phethahala

Moralo oa lieta tsa setempe se futhumatsang o sebetsa

B) TLHALOSO EA MOUPO E HLAHANG

E sebetsa ho li-contours tsohle le li-geometri

Mamello ka lebokoseng la hlobo ka tlase +/-0.3 mm

Tlhaloso ea lieta tse itšetlehileng ka mochine ea 0,2-0,5 mm

Mabota a mahlakoreng a matle a otlolohileng, a mahlakoreng le a boreleli

Ho bopa habonolo

Ho nepahala ho phahameng hoa ho lekana

Li-spaceholders ka meralo eohle e ka khonehang

Moqapi oa lakane oa boikhethelo

Ka digitalization mahala holim'a moralo oa phethahala

Moralo oa lieta tsa setempe se futhumatsang o sebetsa

Apara tšireletso bakeng sa liforomo tsohle tse katiloeng ka tsela e latelang:

A) CARBURIZING(62-68 HRC)

Lebokose la hlobo le lieta tsa setempe li thatafetse (62-68 HRC)

Ho kenella ka thata min. 1,2 limilimithara

B)NITRATING (62-68 HRC)

Lebokose la hlobo le lieta tsa setempe tse nitrate (62-68 HRC)

Ho kenella ka thata min. 0,4 limilimithara

Ha ho na khatello ea kelello e ka hare ha e bapisoa le hlobo e tšoaroang ka carburizing

E khothaletsoa bakeng sa botenya bo bonyenyane ba tepo

Ho nepahala ho phahameng ho feta liforomo tse tšoaroang ka carburizing

Ho latela litlhoko tse tsoang ho bareki, liforomo tsa rona li ka raloa le ho etsoa ka mekhoa ea ho notlela khoele ea weld kapa modular screw.